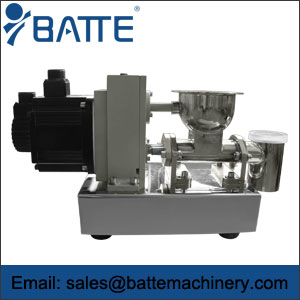

Structural characteristics of double helix feeder

Double-screw conveyor has two-way spiral blades welded on the rotating shaft. According to the different types of conveying materials, there are solid surface, belt surface and blade surface. The spiral shaft of double-screw conveyor has thrust bearing at the end of the material movement direction to give the spiral axial reaction force along with the material. When the fuselage is longer, the bearing should be suspended in the middle and the double-screw feeder rotates. The rotating direction of the rotating shaft determines the direction of material conveying. Generally, double screw conveyor is designed according to single conveyor to design the rotating blade when conveying in reverse, which will reduce the service life of the conveyor.

Scope of application

Scope of application

Double screw conveyor is a continuous conveying equipment widely used in metallurgy, building materials, chemical industry, grain and mechanical processing.

Working principle

Material is added from the inlet and outlet. When the rotating shaft rotates, the material is subjected to the normal thrust of the helical blade. The radial component of the thrust force and the friction force of the blade to the material may rotate around the material axis, but because of the gravity of the material itself and the friction force of the material trough to the material, it does not rotate with the helical blade, but moves along the material trough axis under the action of the axial component force of the normal thrust of the blade.

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould